Welcome to the new website of Victorian Testing and Inspection Services. Founded in 2008, we’re proudly Australian owned and operated.

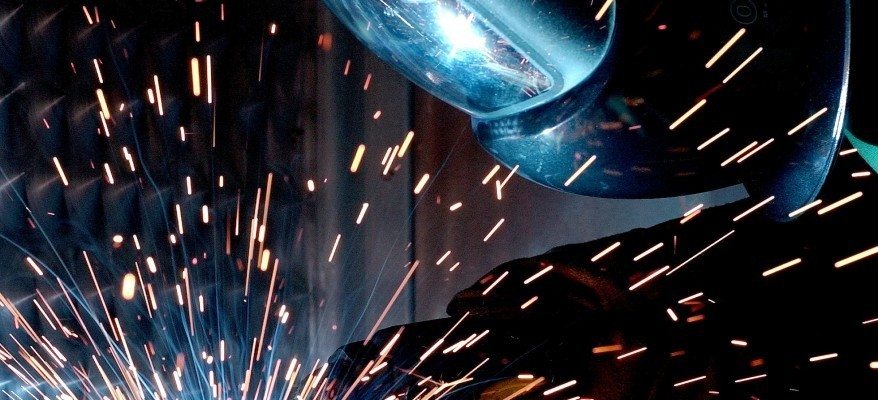

We’re a support service to the power, oil and gas, construction and fabrication industries, providing a range of mechanical and metallurgical inspection and testing services as required.

Our broad range of services includes:

- material identification and certification

- load testing

- testing of PE/HDPE poly welds and electrofusion sockets

- pressure vessel inspections

- weld procedure development, testing and qualification

- welder qualifications

- metallurgical services and failure analysis

- non-destructive testing.

In 2012 we expanded into poly pipe testing – a huge growth area – and, under director Andrew Joiner, we’ve also extended our reach geographically.

We now operate from three sites: Morwell in the Latrobe Valley and the original home of Victorian Testing and Inspection Services; VTS Townsville, which we opened in 2013 and operate as Queensland Testing Services; and Spotswood’s MecTest Laboratories, which we acquired in 2015.

Through affiliation with other specialised quality organisations, we are able to offer a wide range of services throughout Australia and South East Asia.

We’re National Association of Testing Authorities (NATA) accredited and have implemented the following systems to ensure compliance with Australian and international standards:

- Quality System, meeting the requirements of ISO 17025 and 9001

- OH&S Management System, meeting requirements of AS4801

- Environmental Management System, meeting requirements of ISO 14001.

For all our services, quality, impartiality and independence are key deliverables, as is customer focus, hence our mission statement:

“To ensure accurate and timely testing and inspection services and to continuously meet or exceed customer expectations through exceptional service.”

Which means we’re on the ball when it comes to prompt delivery of all results and written reports … in short: we’re here to look after you!